DESCRIPTION

This Kit Includes:

1 x KL03643 BlowTie Diaphragm Spunding Valve

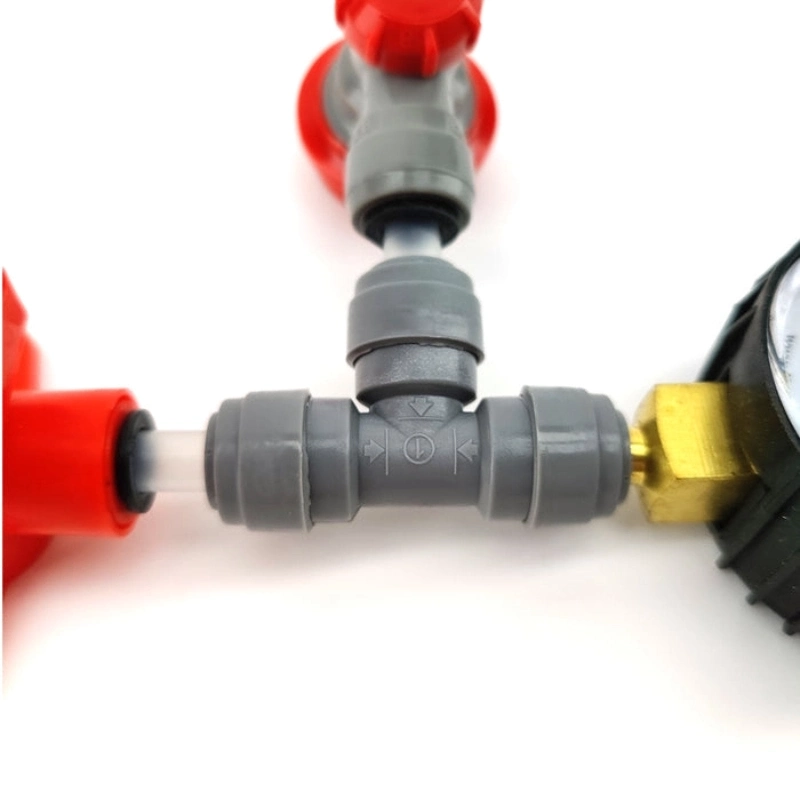

1 x KL02387duotight – 8mm (5/16”) Female x 8mm (5/16”) Female Double Tee Piece

1 x KL06880duotight – 8mm (5/16”) Female x FFL Female Thread

1 x KL148168mm Push In Pressure Gauge 0-15psi

1 x KL02967 Premium Ball Lock Disconnect (MFL) Grey/Gas

2 x KL18012 8mm Rigid Plaster Joiner

This kit has been designed for simplicity and ease of putting together.

If you want to control the pressure retained in a pressure vessel that is releasing pressure then the BlowTie Diaphram Spunding Valve is the tool for the job.

For more information about the many benefits of pressure fermentation please see this article.

The adjustment knob on the top of the unit makes it easy to increase and decrease the set pressure.

This BlowTie unit can be easily disassembled for cleaning using a Phillips head screwdriver.

BlowTie Complete Kit (Diaphragm Spunding Valve)

This Kit Includes:

1 x KL03643 BlowTie Diaphragm Spunding Valve

1 x KL02387duotight – 8mm (5/16”) Female x 8mm (5/16”) Female Double Tee Piece

1 x KL06880duotight – 8mm (5/16”) Female x FFL Female Thread

1 x KL148168mm Push In Pressure Gauge 0-15psi

1 x KL02967 Premium Ball Lock Disconnect (MFL) Grey/Gas

2 x KL18012 8mm Rigid Plaster Joiner

Pressure Fermentation

With pressurised fermentation becoming ever more popular it has become increasingly important to have a method of regulating and controlling this residual pressure from the fermentation process. The BlowTie has been designed specifically for this reason.

For more information about the many benefits of pressure fermentation please see this article.

Pressure Transfers

When transferring from keg to keg, keg to bottle, or fermenter to keg it's often a good idea to have head pressure in the keg you are filling into especially if you are transferring a beverage that is carbonated. For this reason the BlowTie can consistently control this head pressure giving you more consistent results and without losing carbonation in the process.

Traditional spunding valves that use a simple spring against a seal are flawed right from the beginning as the physical aspects of the design dictate that you will have a significant difference between the opening pressure and closing pressure during operation. Brewers have tolerated this imperfection for long enough and now you can control these pressures far more accurately.

The BlowTie has been made completely differently taking advantage of a diaphragm to actuate the sealing mechanism that will release pressure from the pressure vessel with much more accurate control pressure.

Instructions:

Use the yellow adjustment knob to control the pressure coming out of the pressure vessel. Clockwise is higher pressure and anticlockwise is lower pressure.

We would recommend gassing a keg to a known pressure e.g. 15psi then attach your Blow Tie Kit to the keg and adjust to 10psi.

Specifications:

1. Made from food-grade acetal

2. Stainless screws

3. 8mm (5/16") push on both sides

4. 0-15psi pressure rating

Please note: The joiners are a semi-permanent fitting. You will not be able to remove the fittings easily. If you would like to have a completely removable fitted kit we would suggest using EVABarrier 4mm ID or 5mm ID hose as the joining pieces.

Below is a video from Gash. this is a great video to have a look at if you want to see the product in action.

If you accidentally get beer into this device you can easily take it apart for cleaning. Just see this video here:

Here is another review covered by David Heath in Europe. He has also done a comparison between the Blowtie and other conventional spunding valves.

If you are looking for a compact digital gauge with backlight illumination click here.

SHIPPING

Shipping prices are calculated on the checkout page based on the size, weight, and where it needs to be delivered. You can be confident that you will receive accurate and fair shipping rates specifically tailored to suit your individual purchase.

Once an order is placed, please note that KegLand is unable to make changes or additions to the order or modify the shipping information. If any changes are required, it is the customer's responsibility to directly contact the shipping provider and arrange for redirection or any necessary adjustments.

Read More: Shipping Policy